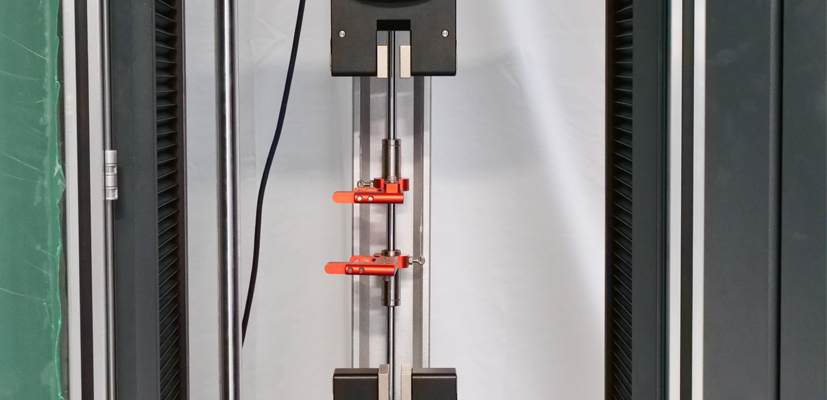

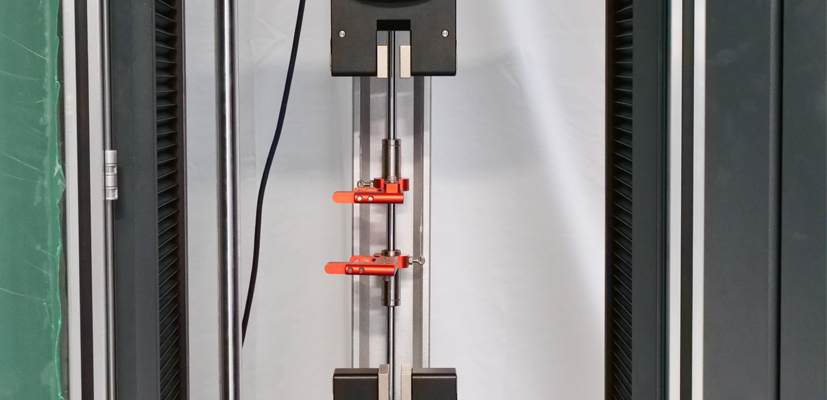

Ao realizar um ensaio de tração em um material, a etapa mais crítica é a medição do alongamento. A utilização exclusiva dos dados de deslocamento da travessa da máquina de ensaio apresenta uma limitação fundamental: o movimento da travessa inclui folga da máquina, deslizamento da extremidade de fixação do corpo de prova e até mesmo deformação plástica localizada do corpo de prova no dispositivo de fixação. Esses erros interferem significativamente na medição precisa da deformação real dentro do comprimento útil do corpo de prova. Portanto, um extensômetro atua como o "olho de águia" do ensaio de tração de materiais, focando precisamente no comprimento útil do corpo de prova e medindo diretamente a deformação real dentro desse comprimento.

Um extensômetro é essencialmente um instrumento de medição de deformação de alta precisão. Ele pode ser de contato (como um extensômetro de lâmina, que utiliza uma lâmina para contato direto com a amostra) ou sem contato (como um extensômetro de vídeo ou um extensômetro a laser, que utiliza rastreamento óptico para acompanhar pontos marcados na superfície da amostra). Seu objetivo é eliminar todas as interferências e capturar a resposta real de deformação do material dentro do comprimento de medição. Ele pode medir com precisão propriedades mecânicas importantes de um material, incluindo o módulo de elasticidade (inclinação inicial da curva tensão-deformação), a resistência à extensão não proporcional especificada (como Rp0,2), a resistência ao escoamento e o alongamento uniforme. Esses parâmetros críticos são altamente dependentes do alongamento mínimo da amostra durante os estágios de deformação elástica e plástica.

A utilização de um extensômetro é uma etapa crucial nos testes:

1. Para extensômetros de contato, alinhe a lâmina e pressione-a suavemente contra um ponto de marcação na seção de medição do corpo de prova ou em um ressalto específico, garantindo o contato perpendicular entre a lâmina e o corpo de prova. Uma leve pré-carga deve ser aplicada à lâmina para eliminar folgas, mas não em excesso a ponto de causar marcas localizadas ou interferir na deformação livre do corpo de prova. Para extensômetros sem contato, um padrão de manchas nítido e de alto contraste ou um ponto de marcação deve ser criado na seção de medição do corpo de prova. O foco, o ângulo e a iluminação da lente devem ser ajustados com precisão para garantir o rastreamento estável do ponto de marcação durante todo o ensaio.

2. Antes dos testes formais, o extensômetro deve ser calibrado utilizando um bloco padrão para estabelecer uma relação de conversão precisa entre o sinal de saída e a deformação real. Após a instalação do extensômetro e antes de aplicar qualquer carga, execute uma operação de "zero zero" no software para eliminar a pré-deformação de instalação e a deriva zero do sistema. Alguns sistemas também exigem um procedimento de "configuração do comprimento de referência" para inserir o comprimento de referência real do extensômetro.

3. Inicie o ensaio de tração. O extensômetro transmite o sinal de deformação para o controlador ou sistema de aquisição de dados em tempo real. O estado do extensômetro deve ser monitorado atentamente para evitar contato ou deslizamento acidental. É particularmente importante remover prontamente e com cuidado alguns extensômetros em contato, pouco antes de o material entrar ou atingir o limite de escoamento (por exemplo, antes que ocorra estricção significativa), para evitar o recuo violento após a fratura do corpo de prova, o que poderia danificar o sensor, que é caro. Os extensômetros sem contato, por outro lado, normalmente monitoram todo o processo até a fratura do corpo de prova, capturando completamente o processo de estricção e fratura.

As propriedades mecânicas dos materiais (especialmente o módulo de elasticidade, a deformação de escoamento e o alongamento) exigem uma precisão extremamente alta na medição da deformação. Os extensômetros capturam com precisão, em tempo real e continuamente, deformações mínimas dentro do comprimento de medição, eliminando erros de equipamento, erros humanos e deformações perdidas em etapas, proporcionando uma garantia fundamental para a confiabilidade dos resultados dos testes. Desde o aço de imponentes pontes até componentes microeletrônicos sofisticados, os dados precisos de deformação fornecidos pelos extensômetros sempre foram um pilar indispensável da pesquisa moderna em ciência dos materiais e do projeto de segurança em engenharia. Eles nos permitem compreender claramente a resposta real dos materiais sob a ação de forças, fornecendo uma base sólida para a construção de um mundo mais seguro.

E-mail:

hello@utstesters.com

Telefone direto: +86 152 6060 5085

Telefone: +86-596-7686689

Web:

www.uttesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085