O Teste de Abrasão Martindale é um teste de produtos têxteis que utiliza o sistema padrão Martindale para determinar a resistência à abrasão de um tecido. A resistência à abrasão refere-se à resistência de um tecido ao atrito repetido com outros materiais. A resistência à formação de bolinhas é um indicador-chave de qualidade dos produtos têxteis, impactando diretamente sua durabilidade e desempenho.

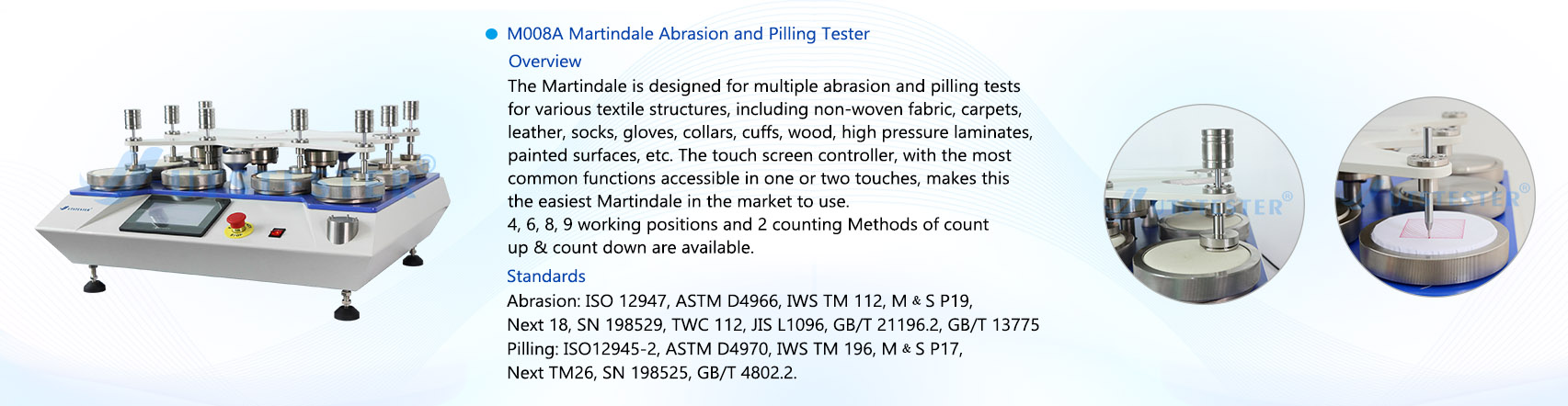

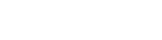

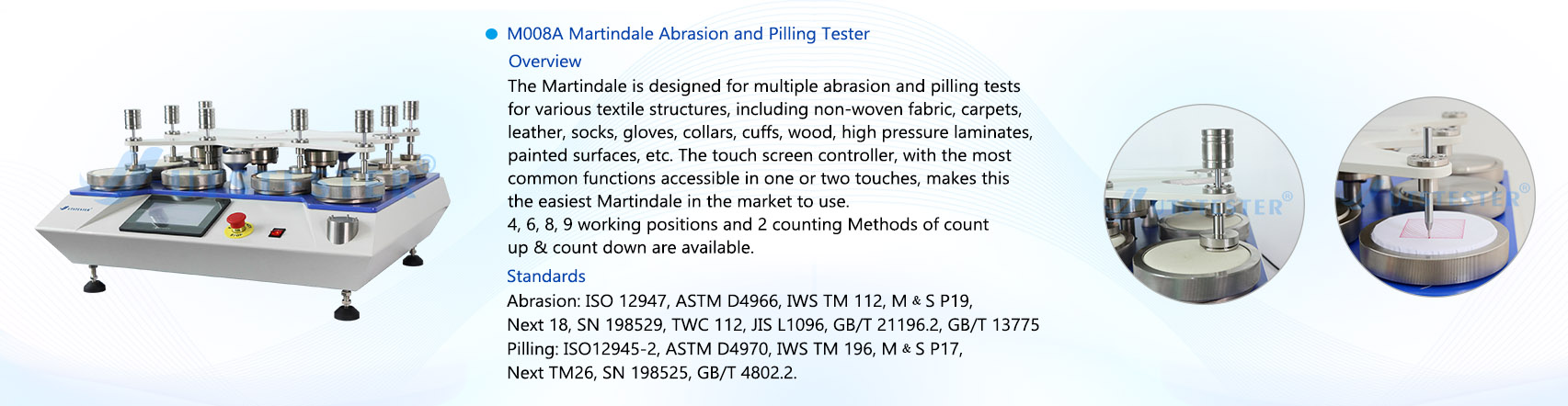

Testador de Abrasão Martindale

é usado para testar a resistência à abrasão e à formação de bolinhas de um tecido.

1. Padrões de teste Martindale

Como diferentes países e regiões possuem padrões distintos, podemos categorizá-los em padrões internacionais, padrões americanos, padrões europeus e padrões chineses. Os detalhes são os seguintes:

1.1 Normas Internacionais

ISO 12947.2—1998 Teste Martindale para Tecidos — Parte 2: Medição de Danos em Amostras

ISO 12947.3—1998 Teste Martindale para Tecidos — Parte 3: Medição de Perda de Massa

ISO 12947.4—1998 Teste Martindale para Tecidos — Parte 4: Medição de Mudança de Aparência

1.2Sociedade Americana de Materiais (ASTM)

ASTM D4966-2010

1.3 Normas da UE

EN ISO 12947.2-1998 - Determinação da resistência do tecido à abrasão e à formação de bolinhas pelo método Martindale - Parte 2: Medição da quebra da amostra

EN ISO 12947.3-1998 - Determinação da resistência do tecido à abrasão e pilling pelo método Martindale - Parte 3: Medição da perda de massa

EN ISO 12947.4-1998 - Determinação da resistência do tecido à abrasão e à formação de bolinhas pelo método Martindale - Parte 4: Medição da mudança de aparência

1.4 Padrões Chineses

GB/T 21196.2-2007 - Determinação da resistência do tecido à abrasão e pilling pelo método Martindale - Parte 2: Medição da quebra do corpo de prova

GB/T 21196.3-2007 - Determinação da resistência do tecido à abrasão e pilling pelo método Martindale - Parte 3: Medição da perda de massa

GB/T 21196.4-2007 - Determinação da resistência do tecido à abrasão e à formação de bolinhas pelo método Martindale - Parte 4: Determinação da alteração da aparência

2. Como é realizado o Teste de Desgaste Martindale?

2.1 Preparação: Verifique o estado do instrumento e prepare a amostra e a lixa.

2.2 Instalação da amostra: Fixe a amostra no suporte e ajuste a força de contato entre a amostra e a lixa.

2.3 Configurações dos parâmetros de teste: defina a velocidade de rotação, a carga de desgaste e outros parâmetros de acordo com os requisitos do teste.

2.4 Início do teste: ligue o instrumento, execute o teste de desgaste e registre o desgaste da amostra.

3. Observação: O pano de fricção padrão deve ser substituído antes de cada nova amostra ser testada ou após 50.000 ciclos. Verifique se o pano de fricção padrão apresenta contaminação ou desgaste e substitua-o se necessário. Este método não é adequado para tecidos com espessura superior a 3 mm. As amostras podem ser lavadas ou lavadas a seco antes do teste.

4. Métodos de avaliação de resultados de testes

Existem três métodos de Martindale para avaliar a resistência à abrasão de tecidos: o método de quebra da amostra, o método de perda de massa e o método de alteração da qualidade da aparência. O método de quebra da amostra é o mais comumente utilizado dos três métodos, pois oferece erro mínimo, resultados de teste intuitivos e claros e facilita a comparação da resistência à abrasão de diferentes tecidos. O método de perda de massa e o método de alteração da qualidade da aparência são mais complexos de avaliar, mas podem refletir a resistência à abrasão de uma amostra em diferentes estágios de atrito. São altamente práticos para fabricantes e instituições de pesquisa na análise do uso de tecidos.

E-mail:

hello@utstesters.com

Direto: + 86 152 6060 5085

Telefone: +86-596-7686689

Rede:

www.utstesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085