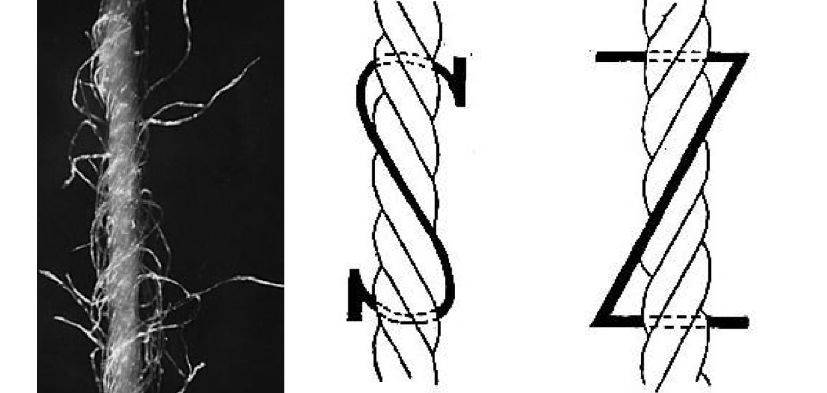

A torção não afeta apenas as propriedades de tração do fio, mas também influencia seu diâmetro, volume específico, maciez e rigidez. Esses fatores, por sua vez, impactam o desempenho de cobertura do tecido, o isolamento térmico, a capacidade de recuperação de vincos, a taxa de absorção de tinta e a permeabilidade. A torção também afeta a felpudez da superfície do fio, tornando-a um importante indicador das características estruturais do fio.

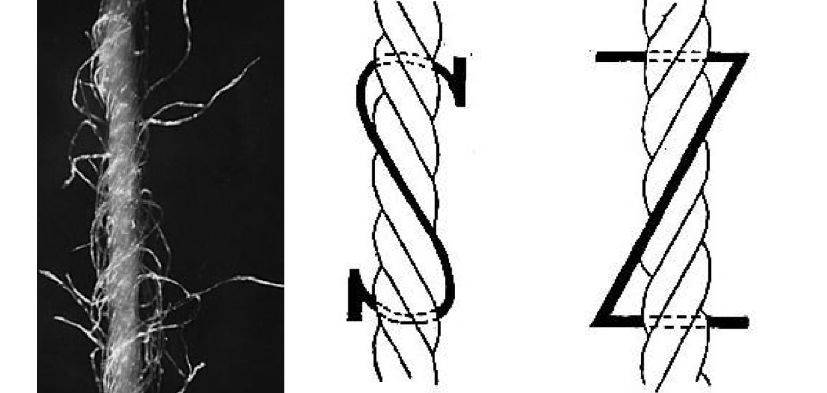

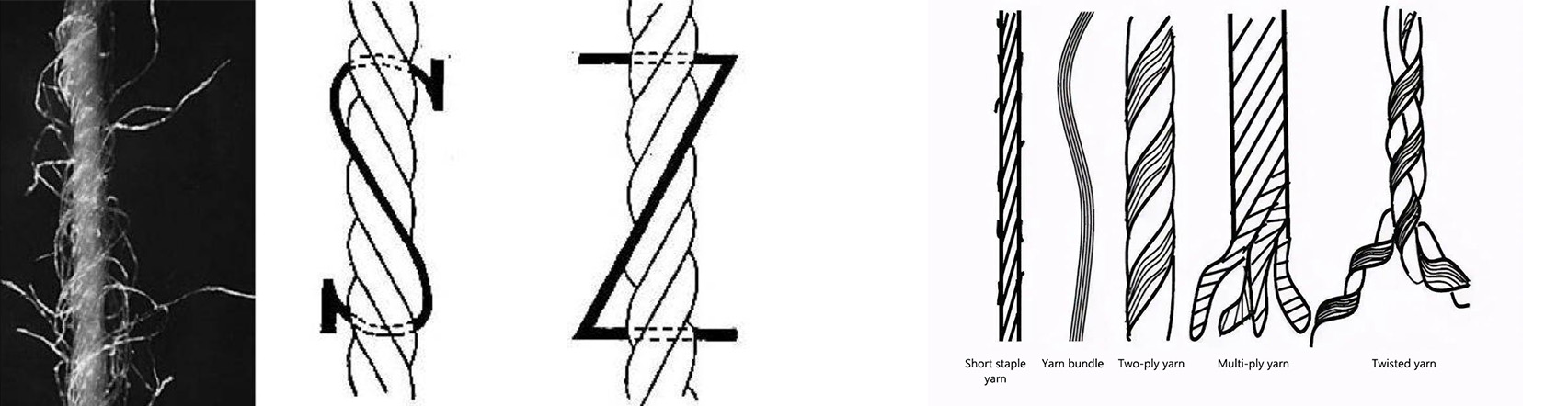

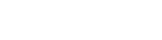

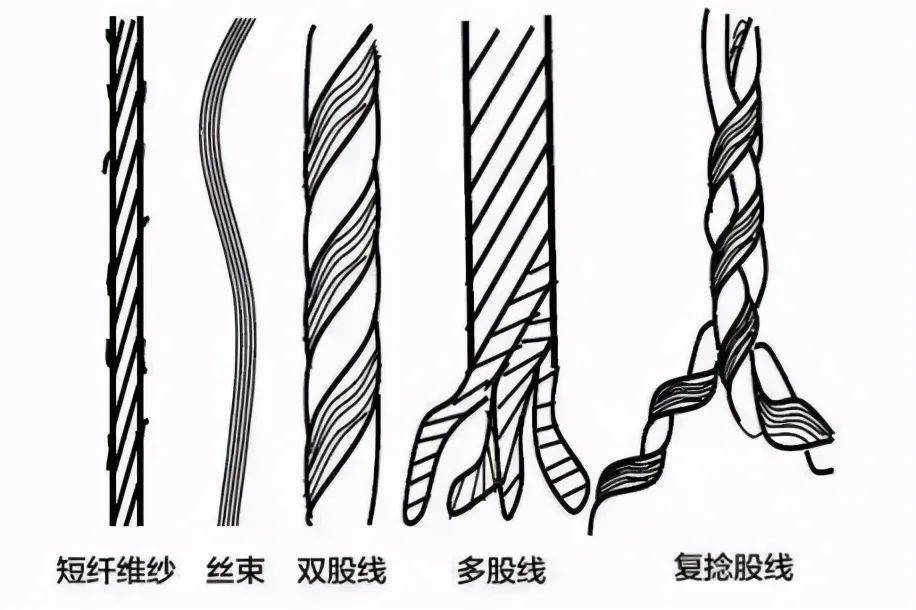

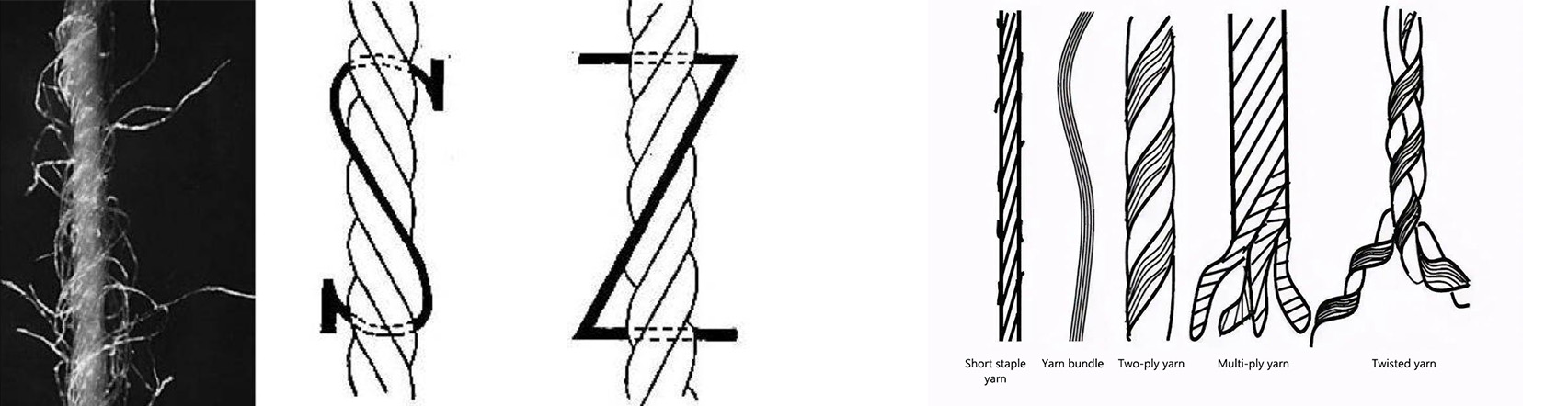

Além de usar o coeficiente de torção e torção para descrever as características de torção do fio, a direção da torção dentro do fio também é crucial. A direção da torção refere-se à direção inclinada das fibras ou fios individuais dentro de um fio torcido após a torção. Existem dois tipos de direção de torção no fio: torção em S (torção no sentido horário) e torção em Z (torção no sentido anti-horário). Fios simples são geralmente torcidos na direção Z, enquanto a torção em S é comumente usada em fios torcidos.

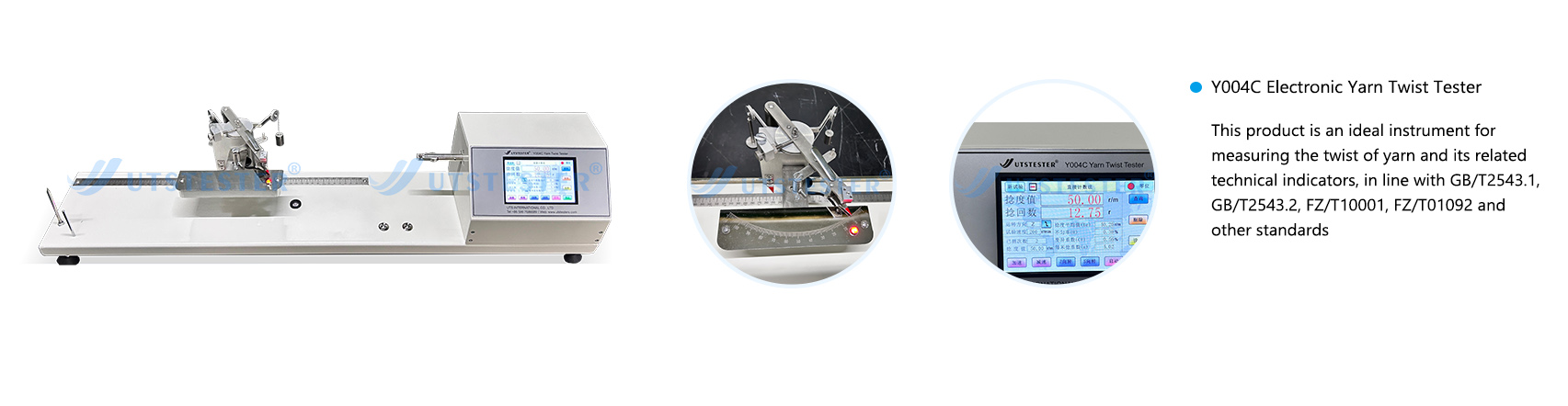

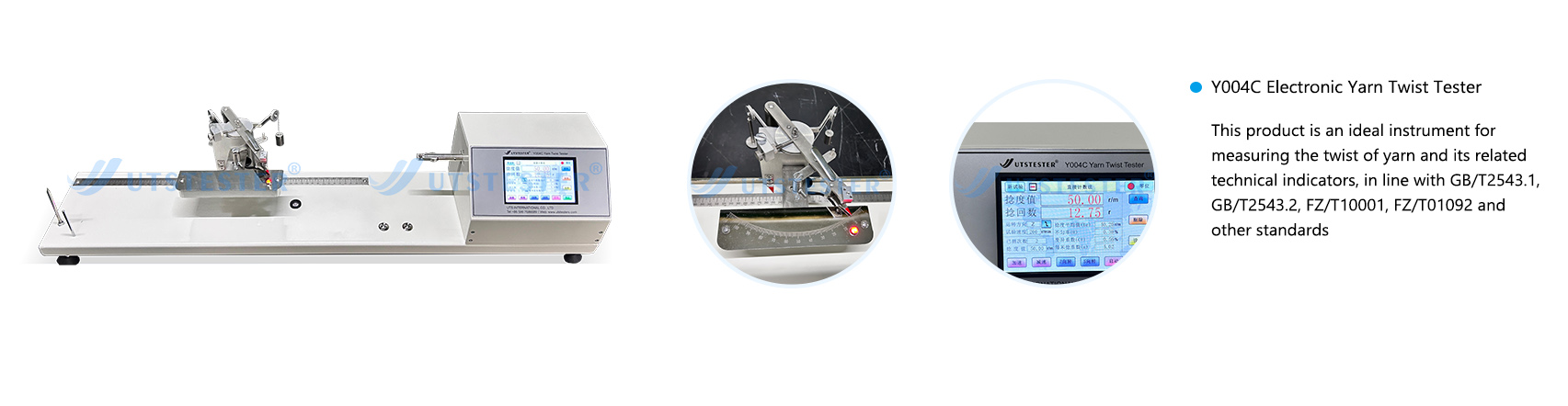

O comumente usado

teste de torção

Os métodos são contagem direta e destorção e torção. O método de contagem direta é geralmente usado para fibras e fios curtos, enquanto o método de destorção e torção é usado para fios finos. Além disso, existem também métodos secundários e terciários de destorção e torção, métodos de deslizamento, etc.

1. Método de contagem direta

Uma extremidade da amostra é fixada, enquanto a outra extremidade é girada na direção da destorção até que as fibras do fio estejam completamente esticadas e paralelas. A torção não torcida é então contada para determinar a contagem de torções por unidade de comprimento da amostra. O método de contagem direta é o método mais básico para determinar a torção do fio, e seus resultados são relativamente precisos, frequentemente servindo como padrão para avaliar a precisão de outros métodos.

No entanto, este método tem baixa eficiência de trabalho. Se as fibras do fio forem torcidas, elas são difíceis de separar em fios paralelos, e separar as fibras pode fazer com que o fio se quebre facilmente. O método de contagem direta é geralmente usado para contar a contagem de torções de fios grossos ou fios torcidos, enquanto o método de contagem de fios preto e branco pode ser usado para testar fios finos. Isso envolve alimentar um fio grosso preto e um fio grosso branco no mesmo fuso para produzir um fio fino com listras pretas e brancas alternadas. A amostra é fixada no medidor de torção e destorcida da mesma maneira que o método de contagem direta. À medida que a destorção progride, a distância entre as seções preta e branca do fio aumenta, facilitando a contagem manual. Geralmente, destorcer para aproximadamente metade da contagem total de torções permite a contagem manual da contagem de torções restante. A contagem total de torções no fio é a soma da contagem de torções não torcidas do medidor de torções e a contagem de torções restante da contagem manual.

2. Método de remoção e adição de torção

O método de remoção e adição de torção baseia-se na suposição de que, sob uma determinada tensão, o alongamento do fio após a remoção da torção é igual ao encurtamento do fio durante a adição de torção reversa. Um aparelho de teste típico.

3. Fatores que afetam o teste de torção

3.1 Pré-tensão

A pré-tensão para o método de destorção e retorção varia entre países e regiões. A pré-tensão excessiva pode fazer com que o ponteiro retorne a zero lentamente durante a torção reversa, aumentando assim a torção durante a torção reversa. No método de deslizamento, isso pode levar ao deslizamento prematuro da fibra. Por outro lado, a pré-tensão insuficiente pode resultar em torção relativamente reduzida durante a torção reversa, fazendo com que os valores de teste sejam menores durante o método de destorção e torção. No método de deslizamento e no método de destorção e torção secundária, como os erros causados por mudanças de tensão são levados em consideração, o método de subtração dos erros de duas amostras é adotado, minimizando assim a influência da tensão.

3.2 Valor de alongamento admissível

Após o destorcimento do fio, o alongamento da amostra é medido. O valor de alongamento permitido definido para o limite de alongamento desempenha um papel na prevenção do deslizamento da fibra durante o processo de destorcimento. Experimentos mostraram que, em testes de destorcimento e torção, quanto maior o valor de alongamento permitido, maior o valor de torção medido. No entanto, se o valor de alongamento permitido for muito grande, o deslizamento da fibra nos pontos fracos do fio afetará significativamente a precisão do experimento. O valor de alongamento permitido está relacionado ao coeficiente de torção; quanto maior o coeficiente de torção do fio, maior o valor de alongamento permitido pode ser selecionado; inversamente, deve ser menor. Geralmente, a faixa de variação dos coeficientes de torção do fio não é grande, portanto, as diferenças nos valores de alongamento permitido também não serão excessivas.

3.3 Desnível do fio

A irregularidade do fio pode afetar os testes de torção. Se o fio apresentar defeitos como neps ou slubs, durante o processo de destorção, a torção original do fio pode não ser totalmente removida antes do início da torção reversa, o que leva a erros de teste maiores. Se houver longas seções de irregularidade no fio, isso afetará a precisão da tensão aplicada, causando erros de teste adicionais.

Em

teste de torção do fio

Se os dados apresentarem desvios significativos, os três fatores acima que afetam o teste podem ser usados como referência para identificar a causa, e fatores humanos não podem ser descartados como fonte de imprecisão dos dados. Independentemente do tipo de teste, ele deve ser conduzido com cuidado e meticulosidade para garantir a precisão científica dos dados.

E-mail:

hello@utstesters.com

Direto: + 86 152 6060 5085

Telefone: +86-596-7686689

Rede:

www.utstesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085