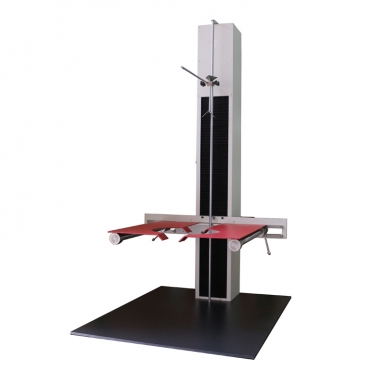

E001N Temperature Humidity Test Chamber

Application

Temperature Humidity Test Chamber is used to determine resistance to hot, cold, dry and moisture property for various material. UTS temperature and humidity chamber is applicable for products quality management of electronic, electrical appliances, food, vehicles, metals, chemicals, building materials, etc.

Standards

| GB/T2423.2-89 High-temperature test method Bb GB2423.1-89 Test A: Low-temperature test method 6 IEC60068-2-1 Low temperature test method Ab GJB150.4-1986 Low temperature test EIA-364-59 Low temperature test IEC60068-2-38 Temperature loops IEC60068-2-78 Constant humidity and heat MIL-STD-202G-103B Humidity test IEC60068-2-30 Humid heat temperature loop EIA-364-31C Humidity resistance GB/T2423.3 Test method for constant humidity and heat GJB150.4-86 Military equipment environmental test method low temperature test GJB150.3-86 Military equipment environmental test method high temperature test GB/T2423.34-2005 Temperature and humidity combined cycle test method |

Features

1. With USB download function, with RS232 interface, curved software, no need for recorder

2. With vacuum glass observation window, more effective direct observation function

3. Refrigerant servo valve flow calculation control. Energy saving 30%, with a dormant function of the resident flow time, energy saving 50% or more

4. Anti-electromagnetic interference controller with SGS certification; with more than 32 numbers of soft program matching, with multiple development and software upgrade function

5. Defrost cycle (800 defrost cycles once, each defrost guaranteed within 2 hours, integrated test to achieve 25% energy saving)

Optional Models

| Model |

E001N-80L |

E001N-150L |

E001N-225L |

E001N-408L |

E001N-800L |

E001N-1000L |

| Inner box volume |

80L |

150L |

225L |

408L |

800L |

1000L |

| Test chamber size (W x H x D)cm |

40×50×40 |

50×50×60 |

60 x 75 x 50 |

80 x 850 x 60 |

100 x 100 x 80 |

100×100×100 |

| External size (D*W*H) (cm) |

133*75*172 |

149* 70*155 |

149*800*168 |

159*100*185 |

179*120*197 |

199*120*197 |

| Weight(kg) |

180 |

210 |

260 |

330 |

450 |

500 |

| Power supply |

1 Phase, AC 220V 50/60Hz |

3 Phase, AC, 380V, 50/60HZ |

Key Specifications

| 1. Temperature |

| The temperature range |

-20 ℃ ~ + 150 ℃ / -40℃ ~ + 150 ℃ / -70℃ ~ + 150 ℃ |

| Temperature deviation |

≦ ± 2.0 ℃ |

| Temperature fluctuations |

± 0.5 ℃ |

| Temperature evenness |

≦ 2.0 ℃ |

| cooling rate |

Heating rate: - 20 ℃ to + 100 ℃ about 35 min (At no-load state, environmental temperature + 25 ℃) Cooling rate: from + 20 ℃ to - 20 ℃ about 45 min (At no-load state, environmental temperature + 25 ℃) |

| 2. Humidity |

| Humidity range |

20%R.H~98%R.H |

| Humidity deviation |

±3.0%RH(>75%RH) ±5.0%RH(≤75%RH) |

| Humidity uniformity |

±3.0%RH (No load) |

| Humidity fluctuation |

±2.0%RH |

| The temperature and humidity performance test is based on the relevant regulations of iec 60068-3 standard.The sensor is placed at the outlet of the unit. |

| Chamber Structure |

| Consist |

The test box adopts the whole structure form, that is, the test box consists of three parts: heat preservation box body, independent refrigeration unit and electric control cabinet Composition. |

| Cabinet size |

Inner box size: W 1000 x H 1000 x D 800 mm Outer box size: W 1200 x H 2035 x D 1815mm (excluding machine stand) |

| Heat preservation box |

External wall material: high quality carbon steel plate with electrostatic color spray treatment on the surface; Inner wall material :SUS304# fog-faced stainless steel plate; Insulation material: hard polyurethane foam insulation layer + glass fiber. |

| Chamber door |

Single door, left open, add heating wire to the door frame to prevent condensation at the door frame at low temperature. |

| observation window |

W 460 x H 560mm observation window is installed on the door of the box. Multi-layer hollow electrothermal coated glass can effectively keep warm and prevent condensation. |

| Lighting device |

LED lighting device, installed in Windows |

| Heater |

High quality nickel-chrome wire electric heater, contactless control mode (SSR). |

| Humidifier |

Water basin heating and humidifying method; Stainless steel armor heater; Heater control mode: contactless control mode (SSR); Water level control device, heater dry - burning device. |

| The condensate outlet hole |

equipped with the studio condensate and the unit condensate drain hole. |

| Electrical outlet & cord hole |

One for each side of left and right chamber, diameter 50mm, equipped with rubber isolation plug and rubber cover. |

| Sample frame |

Duas camadas de estrutura de amostra de aço inoxidável com altura ajustável e peso de carga de 30kg/camada. |

| rodízio em movimento |

Incluindo rodízio móvel |

| Gabinete de controle de distribuição de energia . |

Disjuntor de energia geral e protetor de superaquecimento |

| Sistema de água complementar |

A bomba de água fornece abastecimento de água automático |

fotos de demonstração

Materiais a serem testados

Pacote de remessa de exportação

produtos relacionados

E002A Câmara de pulverização de sal E002C Câmara húmida e seca de sal composto E002W-8m3 Testador de pulverização de sal M0025BN Câmara acelerada por UV

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085