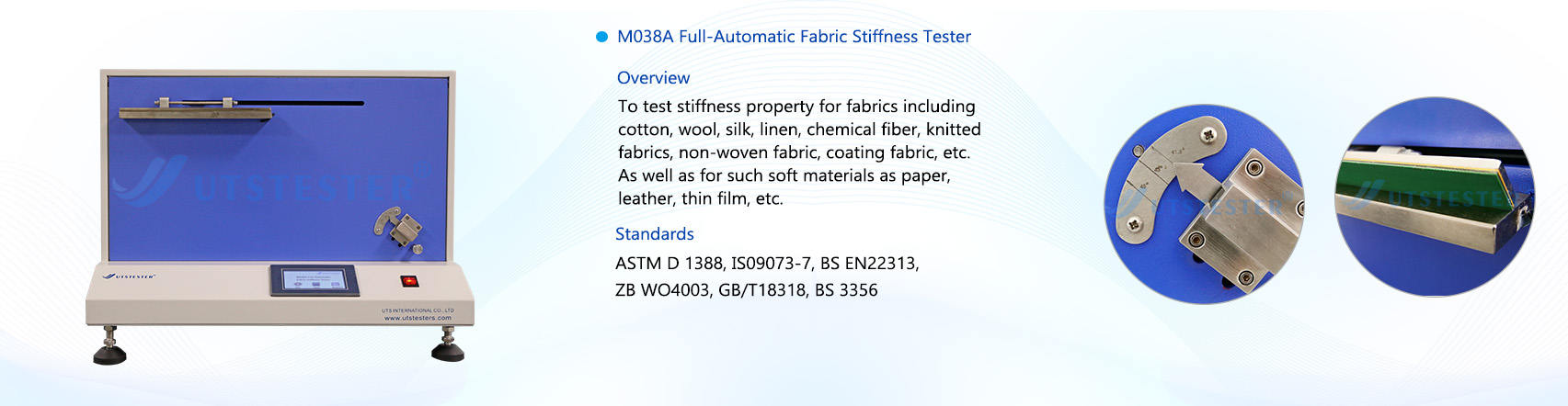

Teste de rigidez de tecido totalmente automatizado

serve como um método crítico para avaliar a resistência de um tecido à flexão (rigidez e maciez), amplamente aplicado no controle de qualidade de têxteis como algodão, lã, fibras sintéticas e têxteis para o lar. Seu princípio básico envolve a medição automática da deformação por flexão de amostras de tecido sob condições específicas por meio de dispositivos mecânicos para calcular os valores de rigidez. Este método oferece vantagens como alta precisão, excelente repetibilidade e redução de erros humanos. A seguir, detalhamos o método de teste de rigidez de tecidos totalmente automático em seis dimensões: princípio do teste, base padrão, estrutura do instrumento, procedimento operacional, processamento de dados e precauções.

I. Princípio de teste

A rigidez do tecido representa fundamentalmente a resistência de um tecido à deformação por flexão, intimamente relacionada ao tipo de fibra, estrutura do fio, trama do tecido e processos de acabamento (como revestimento ou calandragem).

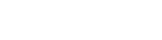

Os testes totalmente automatizados empregam o "método da viga em balanço" (a abordagem predominante): uma extremidade da amostra de tecido é fixada como um "balanço", enquanto a outra extremidade fica pendurada livremente. O instrumento aplica automaticamente uma pequena força externa (ou depende exclusivamente do peso da própria amostra) para dobrar a amostra em um ângulo específico (por exemplo, 45°, 30°, 15°). O comprimento de flexão (L) ou momento fletor (M) na extremidade livre é registrado nesse ângulo. Esse valor é então combinado com a massa da amostra por unidade de área (g/m²) para calcular o índice de rigidez.

Comprimento de Curvatura (L): A distância horizontal que a extremidade livre se estende além da extremidade fixa quando a amostra é dobrada em um ângulo especificado, medida em cm.

Valor de Rigidez (S): Comumente expresso como “comprimento de flexão × massa por unidade de área” (unidade: mg·cm). Valores mais altos indicam maior rigidez do tecido.

II. Padrões de Referência

Os padrões de teste em diferentes países/regiões especificam requisitos para dimensões de amostras, ângulos de curvatura, condições ambientais, etc. Os padrões comuns incluem:

GB/T 18318-2009 Têxteis — Determinação do comprimento de curvatura de tecidos — Método Cantilever

ISO 9073-7:1998 Têxteis — Métodos de ensaio para não-tecidos — Parte 7: Determinação do comprimento de flexão e da rigidez de flexão

AATCC 124-2020 Avaliação da aparência, lisura e rigidez do tecido

JIS L1096:2020 Métodos de teste para têxteis

III. Procedimento de teste

Usando GB/T 18318-2009 (ângulo de curvatura de 45°) como exemplo:

1. Preparação da amostra

Selecione aleatoriamente pelo menos 5 amostras de diferentes áreas da amostra de tecido. Cada amostra deve medir 25 mm (largura) × 150 mm (comprimento). Teste 5 amostras nas direções do urdume e da trama para avaliar as diferenças de rigidez entre urdume e trama.

Evite bordas de tecido (≥10 cm de distância da borda) e defeitos (por exemplo, furos, manchas de óleo). As bordas da amostra devem ser retas (cortadas com um cortador específico para evitar bordas desfiadas).

Condicionamento Ambiental:

Equilibre as amostras em condições normais de temperatura e umidade por pelo menos 24 horas (20 ± 2 °C, 65 ± 4% UR). Mantenha as condições estáveis durante todo o teste (evite que o fluxo de ar interfira na curvatura da amostra).

2. Calibração de instrumentos

Antes do teste, calibre o instrumento usando um bloco de calibração padrão (tira de metal com comprimento de curvatura conhecido):

Fixe o bloco de calibração no dispositivo e ajuste o ângulo de curvatura para 45°;

Inicie o teste. Se o comprimento de curvatura exibido se desviar ≤ 0,1 mm do valor padrão do bloco de calibração, o instrumento está funcionando corretamente; caso contrário, ajuste o sensor óptico ou a precisão mecânica.

3. Configuração e teste de parâmetros

Ligue o instrumento e seu software, selecione o padrão de teste (por exemplo, GB/T 18318-2009) e defina os parâmetros:

Ângulo de curvatura: 45°;

Direção do teste: Urdidura (ou trama);

Quantidade de amostra: 5 peças (por conjunto);

Velocidade de movimento: 5 mm/s (recomendação padrão).

Fixação da amostra:

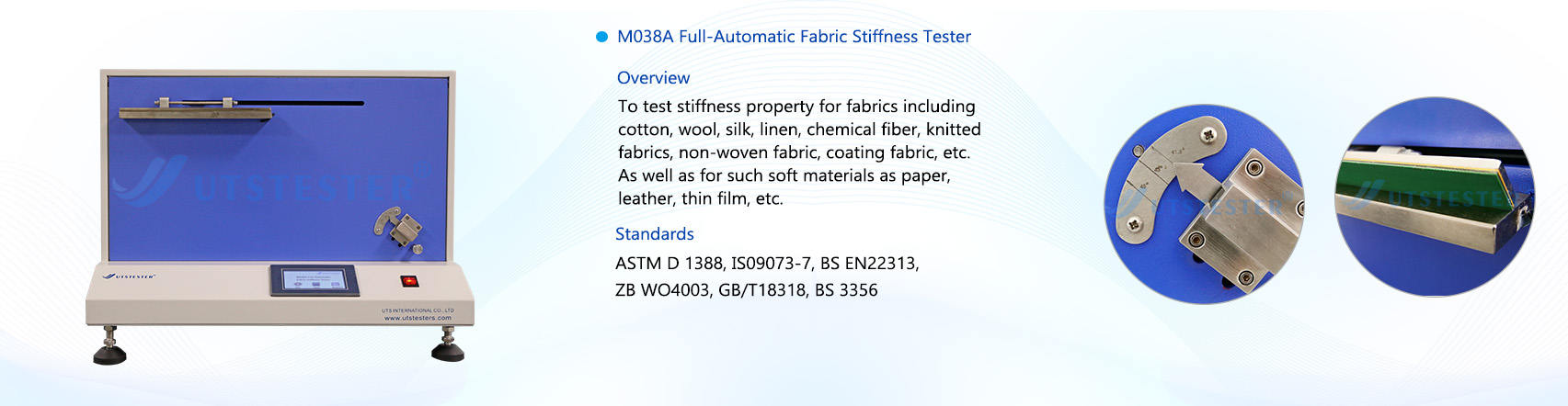

Coloque uma extremidade (longitudinalmente) da amostra no suporte, certificando-se de que ela fique plana contra o suporte, sem tensão ou folga. Após a fixação, a extremidade livre da amostra deve ficar pendurada naturalmente para baixo.

Iniciar teste:

O instrumento aciona automaticamente o dispositivo para se mover, estendendo gradualmente a extremidade livre da amostra para iniciar a flexão;

Um sensor óptico monitora continuamente o ângulo de curvatura. Ao atingir 45°, o dispositivo para de se mover e o software registra automaticamente o "Comprimento de Curvatura (L)";

Repita a operação para concluir o teste para todos os espécimes de urdume e trama.

4. Processamento e Relatórios de Dados

O software calcula automaticamente:

Valor de rigidez de um único espécime:

S = L×m (onde m é a massa do tecido por unidade de área, g/m², pré-medida em balança eletrônica com precisão de 0,01g);

A média (Sˉ), o desvio padrão (DP) e o coeficiente de variação (CV% = DP/Sˉ × 100%) para o grupo amostral. O CV% deve ser ≤5% (caso contrário, a reamostragem é necessária para eliminar os efeitos de não uniformidade da amostra).

Geração de relatórios:

O relatório deve incluir: nome da amostra, composição do tecido, padrão de teste, temperatura/umidade, comprimento de curvatura da urdidura/trama, valor de rigidez da urdidura/trama, valor médio, CV% e ser assinado para confirmação.

E-mail:

hello@utstesters.com

Direto: + 86 152 6060 5085

Telefone: +86-596-7686689

Rede:

www.utstesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085